Thermostatic Steam Trap Repairs

- Cage Units to repair almost any thermostatic steam trap

- East and cost-effective method

- Exclusive steam trap repair index helps you track down the right cage unit to repair your trap

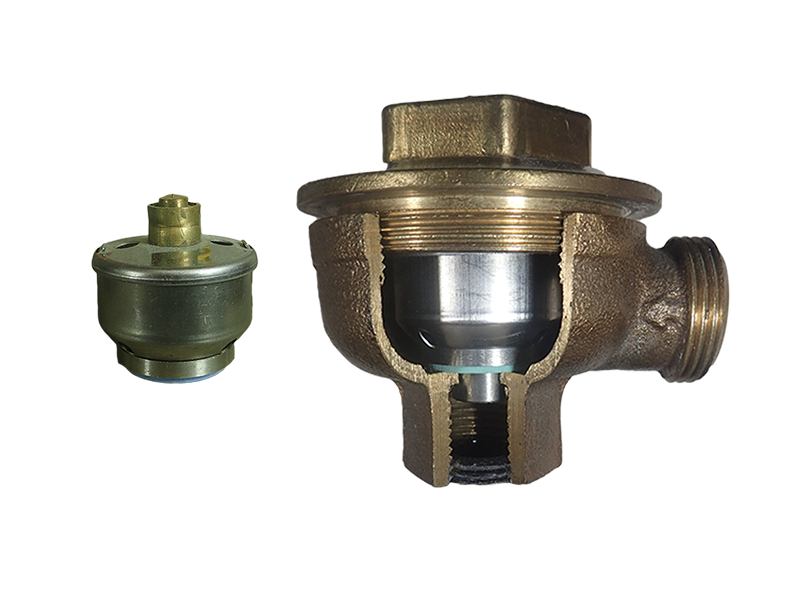

The “Barnes & Jones/Edison Element”, called a Cage Unit, is a self-contained thermostatic repair unit that is designed to repair thermostatic steam traps without taking the trap body off line. Cage Units are 100% factory calibrated and tested, under live steam and condensate, to insure uniform operation in the field. The one-piece, self contained design allows for the ease of on-line repair.

Steam Trap Repair Index

Use the chart below to match up your steam trap to its corresponding cage unit and cover.

Please contact us for questions, quotations and inquiries. We can also help you find the right cage unit and cover.

Contact Us

Do you still have questions? Are you looking for pricing information or to place an order?

Do you have questions about thermostatic steam trap repairs?

What is a cage unit?

The “Barnes & Jones/Edison Element”, called a Cage Unit, is a self-contained thermostatic repair unit that is designed to repair thermostatic steam traps without taking the trap body off line. Cage Units are 100% factory calibrated and tested, under live steam and condensate, to insure uniform operation in the field. The one-piece, self contained design allows for the ease of on-line repair. There are no piping connections that need to be broken or multiple internal components to be removed. The body of the trap acts merely as a housing for the Cage Unit which performs the actual steam trap functions.

How do cage units repair thermostatic steam traps?

Cage Units have actuators that are balanced pressure devices that use vapor pressure within a diaphragm to open and close a valve in a modulating manner dependent upon the temperature surrounding it. The Cage Unit is normally open to expel air and condensate. As saturated steam surrounds the unit, the volatile fill inside the element quickly flashes into a vapor, creating an internal pressure that is equal to the surrounding steam pressure.

This equalization of pressures allow the bellows to expand to its natural length or “closed position”, preventing any steam from passing its point of use. The presence of condensate will cool the bellows and condense the vapor within, reinstating the vacuum, causing the bellows to retract to its open position, thus allowing the condensate to drain from the steam trap.

What are the features of cage units?

- One-piece thermostatic repair kit to repair most makes of thermostatic steam traps

- Calibrated and tested under live steam and condensate to insure precise operation

- All Stainless Steel Valve, Seat, and Body

- Phosphor-Bronze & Monel actuating element

- Repairs virtually all models of thermostatic steam trap manufactured by : Hoffman, Barnes & Jones, Trane, Sarco, Warren Webster, Sterling, Dunham-Bush, and many more

What features do Barnes & Jones & Edison thermostatic steam traps have?

- All working parts are factory calibrated within the “Cage Unit” ensuring absolute uniformity of performance.

- 100% Factory tested under live steam and condensate.

- Heavy Duty Cast Bronze Body.

- Stainless Steel Valve & Seat.

- Forged Brass Cover, Union Nut & Tailpiece.

- Available in angle, straightway, vertical, left hand & right hand piping patterns.

How can you repair thermostatic traps with Edison cage units?

Step 1: Determine the make and model of the existing steam trap to be repaired.

Step 2: Select the proper Edison Kit and colour coded spring (use the PDFs listed above to make your selection).

Step 3: Remove the existing trap cover and all internal components.

Step 4: Drop in the Edison Cage Unit.

Step 5: Reinstall the existing trap cover (or New Cover if required as shown in the ‘Edison Element Tables’ in the ‘Cover’ column).

How can you repair thermostatic traps with Barnes & Jones cage units?

Step 1: Determine the make and model of the existing steam trap to be repaired.

Step 2: Select the correct Barnes & Jones Cage Unit from the table above.

Step 3: Remove the existing trap cover and all internal components.

Step 4: Drop in the Barnes & Jones Cage Unit.

Step 5: Reinstall the existing trap cover (or New Cover if required as shown in the ‘Cage Unit Selection Guide’ in the ‘Cover’ column)