Float & Thermostatic Steam Traps

Parallel Type

- Edison, Sarco, Mepco, Hoffman + More

- Available in 15 to 125+ psi ranges

- Available in 3/4" to 2" pipe sizes

Parallel float & thermostatic steam traps have top inlet and bottom outlet connections that run parallel to each other, often with an inlet and outlet on each side in an ‘H-Pattern’ for the most piping flexibility. Parallel F&T traps can also come in a ‘C-Pattern’ with inlet and outlet connections on one side only.

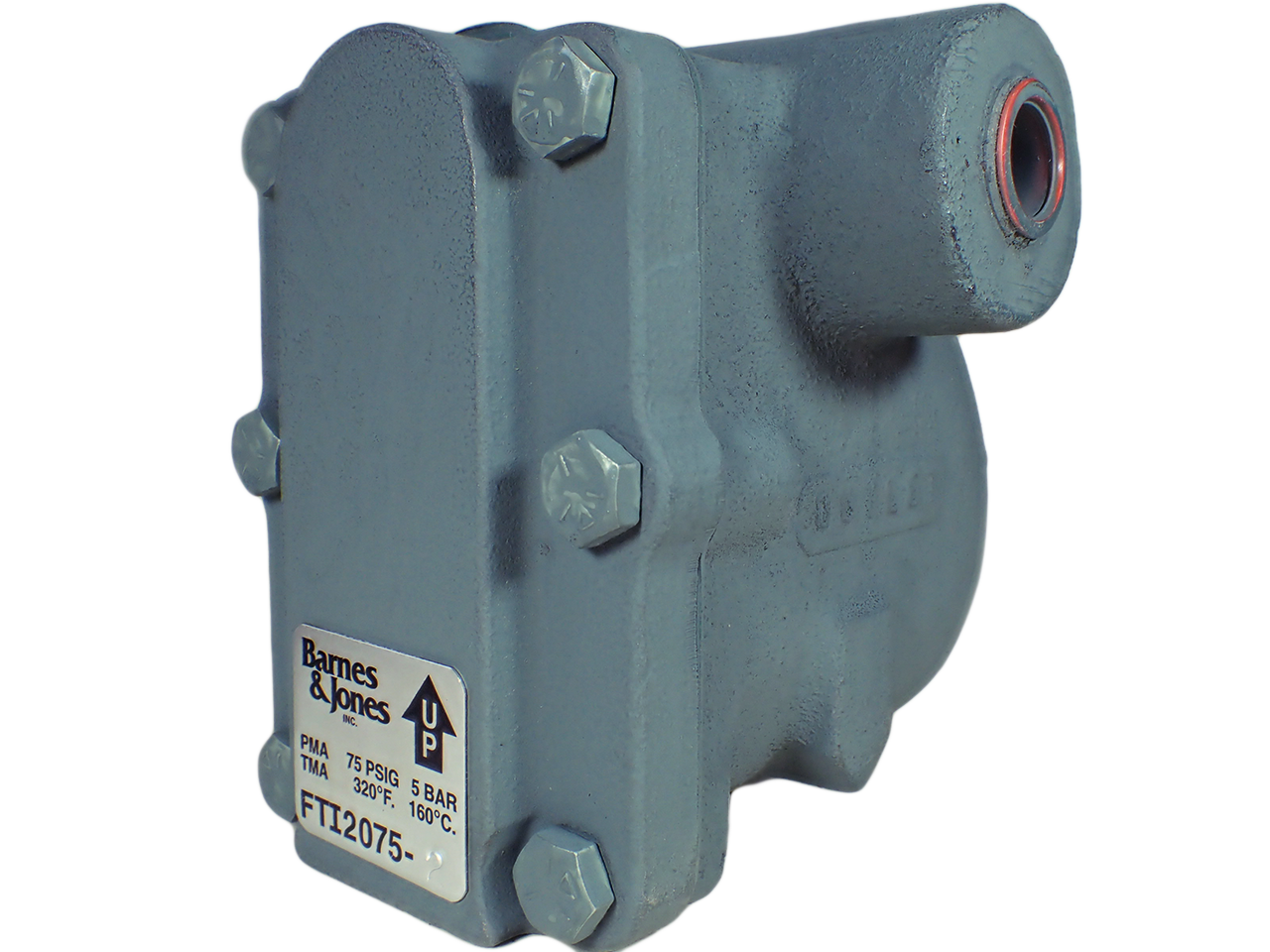

In-Line Type

- Edison, Sarco, Mepco, Hoffman + More

- Available in 15 to 125+ psi ranges

- Available in 1/2" to 2" pipe sizes

In-Line float & thermostatic steam traps are great for when you need straight-through piping, with specially designed heads to provide continuous discharge and avoid steam leakage.

High Capacity Type

- Edison, Sarco, Mepco, Hoffman + More

- Available for operating pressures up to 175+ psi

- Available in 1-1/4” to 2-1/2” pipe sizes

High Capacity float & thermostatic steam traps are made with larger bodies and valve mechanisms so that they can handle larger condensate loads. Connections are usually in a ‘C-Pattern’ parallel configuration.

How do Float & Thermostatic Steam Traps Work?

Float & Thermostatic steam traps operate using two mechanisms: a float-operated valve opens and closes with the liquid level in the trap to let out condensate, while a thermostatic air vent element opens and closes based on temperature to let out air and other non-condensable gases during startup and normal operation.

Available Steam Traps

Scroll the chart below for an overview of float & thermostatic steam traps Keystone commonly supplies.

Please contact us for questions, quotations and inquiries. We can also help you find float & thermostatic steam traps not listed here.

Contact Us

Do you still have questions? Are you looking for pricing information or to place an order?

Get answers to your questions about Float & Thermostatic steam traps

What are the features of parallel series traps?

• H-Pattern

• Available in 3/4” -2” sizes

• Efficient, Continuous, Immediate Discharge.

• High Air Handling capacity reduces Warm Up.

• Repairable on line

• Water sealed valve for zero blow by

• Condensate discharges at saturated steam temperatures

How do parallel series float & thermostatic traps operate?

When the system starts up, the steam pushes air and noncondensable gas out through the thermostatic air vent. As steam enters the trap, the thermostatic air vent responds by snapping shut and stopping the passage of live steam. As the steam gives up its energy and condenses back to water, the water level rises, lifting the float which opens the valve and discharges the condensate into the return line through the trap outlet. When the water level drops, the weight of the float closes the valve maintaining the water seal.

Where can you find parallel series traps?

• Steam Main Drips

• Unit or Space Heaters

• Process Equipment

• Water Heaters

• Chillers and Coils

What are in-line series traps?

The In-line Float & Thermostatic traps Series FTI are designed for all types of low pressure (up to 125 psi) or vacuum steam heating systems and steam process equipment. Typical applications include; unit heaters, space heaters, water heaters, pressing machines, low pressure mains and risers, and replacement of inefficient inverted bucket traps. In-Line Float & Thermostatic traps are especially well suited for apartments, hospitals, office buildings, and schools or wherever quiet operation is necessary.

What are the features of in-line series traps?

• Straight through piping connections

• Unaffected by sudden or wide pressure changes

• Continuous discharge

• Function is not impaired by high back pressure

• Energy efficient

• Simple construction

• On-line repair

• Large air handling capacity

• Conforms to Federal Spec. WWT-696.

How do in-line series steam traps operate?

The opening and closing of the valve is caused by changes in the condensate level within the trap shell. When the water level drops, the weight of the float closes the valve. As condensate enters the traps, the float rises and opens the valve, allowing the condensate to be discharged. The float is designed to provide sufficient buoyancy to overcome the differential pressure across the valve. The internal float and valve configuration is such that the condensate level is always above the valve, creating a continuous water seal at the seat. Air and other gases are freely discharged as they reach the trap through the air vent. The calibrated thermostatic element will close the air vent immediately when the temperature surrounding the element reaches saturated steam temperature.

How are in-line series traps constructed?

In-line Float and Thermostatic traps are compact, of rugged design, with easy access to all interior parts. The body is cast with In-line pipe connections for simple straight through pipe hook-ups. The air vent valve, seat, and the complete valve mechanism are manufactured from stainless steel. The repair kit consists of a complete, factory assembled head which simply bolts on to the body for ease of repair. No pipe connections need to be broken.

What are the features of high-capacity series traps?

• Heavy Duty Construction

• Immediate Condensate Discharge

• Water Sealed Valve Mechanism

• Large Air Handling Capacity

• Continuous Discharge

• Unaffected by Sudden Pressure Changes

• Stainless Steel Valve Mechanism

• Energy Efficient

• Conforms to Federal Spec. WWT–696.

• Operates Against Back Pressure

What are limiting conditions of high-capacity steam traps?

FT2020–8 (2″):

Maximum Operating Pressure (PMO): 20 PSI

Maximum Operation Temperature (TMO): 259°F

Shell Design Conditions:

Maximum Allowable Pressure (PMA): 250 PSI

Maximum Allowable Temperature (TMA): 450°F

FT2175-8 (2”) & FT2175–10 (2½”):

Maximum Operating Pressure (PMO): 175 PSI

Maximum Operation Temperature (TMO): 450°F

Shell Design Conditions:

Maximum Allowable Pressure (PMA): 200 PSI

Maximum Allowable Temperature (TMA): 470°F